picoline

Hosokawa Alpine pico line – Process engineering for research and development

fine grinding – sifting – mixing

With the new pico line series, Hosokawa Alpine offers the widest spectrum for wet or dry processing of ultra-small amounts of powder.

Here is the pico line in its element:

Nanotechnology, pharmaceuticals, cosmetics, agrochemicals, pigments, food colorings, metal, high-performance ceramics, performance polymers, fine chemicals or new functional materials,…

The result is the pico line , a small machine series ,

with an unmistakable specific product language.

You can choose:

1 central platform

5 procedures

9 pico line machines

The UNIQUE , MODULAR CONCEPT for research and development

The UNIQUE , MODULAR CONCEPT for research and development

A pico line machine consists of three parts that can be combined with each other:

- Platform: in 4 different configurations

- Functional modules: dry grinding and sifting, wet grinding, mixing and particle design

- Accessories: depending on the operating mode (continuous, discontinuous) and the batch size, numerous peripheral devices such as mixers, dosing devices, injectors, product separators, …… are optionally available

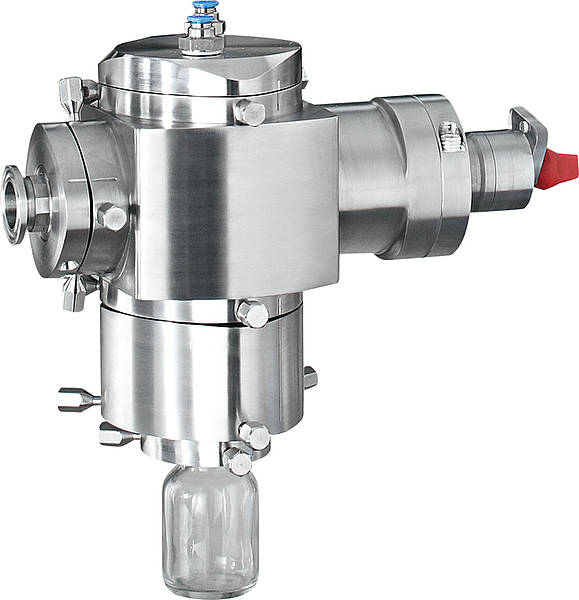

The pico split ® is a very fine classifier for fine classification of fine powders in the separation range of 2 µm - 120 µm. for classification of dry powders according to particle size. The classification takes place according to the centrifugal force countercurrent principle in a rapidly rotating impeller.

The pico zirk ® is a mechanical impact mill for impact grinding with integrated wind sifter of materials up to Mohs hardness 3.5. Produces powder with a steep particle size distribution and narrow particle size spectrum in the fineness range from 8 µm - 120 µm.

The pico jet ® is a fluidized bed opposed jet mill for contamination-free dry fine comminution with integrated wind sifter of materials up to Mohs hardness 10. It produces powder with a steep particle size distribution and sharp upper particle size limits in the finest range of 2 µm - 120 µm.

The pico nizer ® is a spiral jet mill For micronizing dry, relatively soft fabrics up to Mohs hardness 3. Achieve powder fineness in the range of 5 µm - 40 µm. The structure and function largely correspond to the Alpine AS series.

The pico plex ® is a mechanical fine impact mill for dry grinding of soft to medium-hard materials. The structure and function largely correspond to the Alpine UPZ series.

The pico cross ® is a 2-rotor counter-rotating impact mill for dry grinding of soft to medium-hard materials. It achieves the highest powder fineness in the range of 10 µm - 500 µm. The structure and function largely correspond to the Alpine C series.

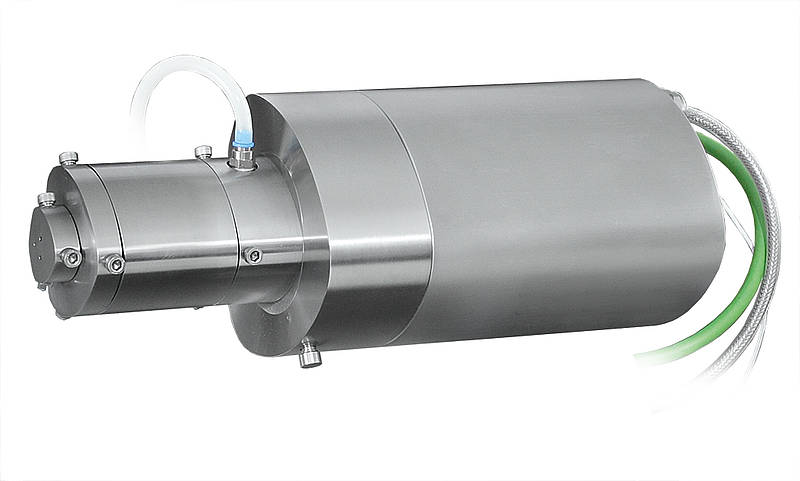

The pico liq ® is a wet agitator ball mill for continuous or batch wet grinding or dispersing of particles in liquids. For wet processing of small to very small product quantities and fineness down to the submicron and nano range. The design and functionality largely corresponds to the Alpine AHM series.

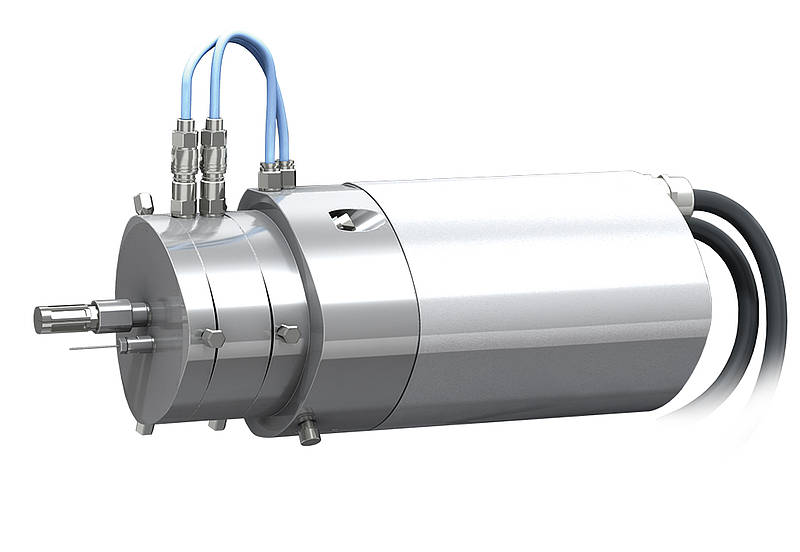

The pico bond ® is a mixing reactor for the mechano-chemical functionalization of dry particles. Dry process for the production of functionalized particles (particle design) and precision mixtures. The design and functionality largely corresponds to the Alpine Nobilta or AMS series.

The pico mix ® is a high-performance batch mixer for dry powder. Intensive mixer with a working volume of 20 ml - 100 ml. Due to the special geometry of the mixing tool and the high shear rate, the powder components are mixed intensively, homogeneously and quickly.